Cutting Optimization Pro 5.18.10.2 Free Download

Cutting Optimization Pro 5.18.10.2 is an advanced software solution designed for optimizing cutting layouts in both one-dimensional (1D) and two-dimensional (2D) materials. It is widely used in industries such as woodworking, metal fabrication, glass cutting, textile manufacturing, and construction, where efficient material usage and waste reduction are essential.

Key Features of Cutting Optimization Pro 5.18.10.2

1. 1D and 2D Cutting Optimization

Cutting Optimization Pro is capable of performing both 1D (linear) and 2D (sheet) cutting optimizations.

- 1D Optimization is used for materials such as pipes, rods, tubes, bars, and beams, ensuring optimal cutting sequences to reduce waste.

- 2D Optimization is used for sheet materials such as wood, metal, glass, and textiles, arranging cut pieces efficiently to maximize the use of each sheet.

2. Guillotine and Non-Guillotine Cutting

The software supports two cutting strategies:

- Guillotine cutting, where each cut runs from one edge of the material to the opposite edge in a straight line. This method is commonly used in glass cutting, wood panel cutting, and large metal sheet cutting.

- Non-guillotine (nested) cutting, which allows pieces to be placed more flexibly without straight-line cuts. This is beneficial for laser cutting, CNC routing, and plasma cutting applications.

3. Multi-Stage Guillotine Cutting

For complex cutting tasks, the software supports multi-stage guillotine cutting, where each cutting stage can be set to perpendicular or parallel orientations. Users can adjust the number of cutting stages to meet specific production requirements.

4. Unlimited Inventory and Cutting Orders

Cutting Optimization Pro can handle unlimited stock inventory and cutting orders, making it ideal for large-scale production. Users can input as many different material types, sheet sizes, and cutting requirements as needed.

5. Customizable Cutting Parameters

Users have full control over cutting settings, including:

- Blade thickness adjustments for precise calculations.

- Maximal cut length and width settings.

- Breakable parts settings for handling fragile materials.

- Customizable margins and spacing between pieces.

6. Automatic Offcut Management

The software automatically tracks reusable material (offcuts) and stores them back into inventory, helping businesses minimize waste and maximize material reuse.

7. Edge Banding Control

For woodworking and furniture manufacturing, the software includes edge banding settings that allow users to define edge thickness, material type, and finishing requirements.

8. Grain Direction Management

For materials with a grain, such as wood and textiles, the software allows users to specify grain direction, ensuring that cuts maintain the correct visual and structural alignment.

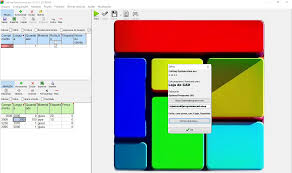

9. Visual Representation and Reports

The software provides graphical layouts of cutting patterns, making it easy for machine operators to follow cutting plans. It also generates:

- Detailed cut lists with dimensions.

- Material efficiency reports.

- Summaries of waste percentage for cost analysis.

10. File Import and Export Support

Cutting Optimization Pro supports multiple file formats, including:

- Importing data from Excel (XLS, CSV), XML, and DBT files.

- Exporting optimized cutting layouts into Word, Excel, HTML, CSV, and XML formats for documentation and further processing.

11. Integration with Other Software

A free SketchUp plugin allows users to export component sizes from their 3D models directly into Cutting Optimization Pro. This feature is particularly useful for woodworkers, architects, and furniture designers.

12. Adhesive Label Printing

To help with material identification, the software can generate and print adhesive labels for each cut piece. These labels can contain information such as dimensions, part numbers, and project references.

13. Multi-Language Support

The software is available in multiple languages, making it accessible to users around the world.

Benefits of Using Cutting Optimization Pro

1. Increased Material Efficiency

By using powerful algorithms, the software significantly reduces material waste and increases the percentage of usable material per sheet or length.

2. Cost Savings

Less waste means lower material costs over time. This is especially important for businesses dealing with expensive materials such as high-quality wood, metal, and glass.

3. Time Efficiency

Automating the cutting layout process saves valuable production time, allowing businesses to handle more projects efficiently.

4. Improved Precision and Quality

Optimized cutting layouts reduce errors and inconsistencies, leading to better final product quality and fewer material defects.

5. Compatibility with CNC Machines

The generated cutting layouts can be easily used with CNC routers, laser cutters, and plasma cutting machines, integrating seamlessly into automated production processes.

6. Scalability for Small and Large Businesses

Whether you are a small woodworking shop or a large manufacturing plant, Cutting Optimization Pro can scale to meet your needs.

System Requirements for Cutting Optimization Pro 5.18.10.2

Minimum Requirements

- Operating System: Windows XP, Windows 7, Windows 10, Windows 11 (32-bit & 64-bit)

- Processor: 90 MHz or higher

- RAM: 8MB or more

- Hard Disk Space: 7MB free space

- Display Resolution: 1024×768 or higher

Recommended Requirements

- Processor: Intel Core i3 / AMD Ryzen 3 or higher

- RAM: 4GB (recommended for large projects)

- Storage: SSD for faster performance

- Graphics: Basic integrated graphics or better

How to Use Cutting Optimization Pro

Install the Software

- Download the installation file from the official website.

- Follow the installation instructions for Windows-based systems.

Input Material and Cutting Requirements

- Add sheet sizes or bar lengths to the inventory.

- Enter the dimensions and quantities of the pieces to be cut.

Optimize the Cutting Layout

- Click the “Optimize” button to generate an optimized cutting plan.

- Review the generated layout for accuracy and efficiency.

Customize and Fine-Tune

- Manually adjust layouts if necessary.

- Modify cutting order, blade settings, or grain direction.

Print Reports and Execute the Cut

- Print cutting layouts and reports.

- Export data to CNC machines or manual cutting teams.

Pricing and Licensing

Single User License: One-time purchase, valid for lifetime use.

Business Licenses: Discounts available for multi-user and enterprise licenses.

Educational License: Free for schools, colleges, and universities for non-commercial use.

Conclusion

Cutting Optimization Pro 5.18.10.2 is an essential tool for anyone involved in cutting materials efficiently. With its powerful optimization algorithms, customizable cutting settings, and detailed reporting tools, this software helps businesses reduce costs, save time, and improve production quality.